Machinery & Facility

At RJS Engineering Works, our strength lies in advanced machinery, skilled manpower, and systematic production processes.

CNC & Machining Infrastructure

We operate a fully equipped machine shop featuring advanced CNC and conventional machines.

- Turning Diameter: up to 350 mm

- Turning Length: up to 500 mm

- Quantity: 4 Machines

- Capable of producing high accuracy shafts, bushes, pins etc.

VMC Machine (Vertical Machining Center)

- High-precision milling

- Complex geometry machining

- Ideal for molds, precision components & custom parts

- Quantity: 1 Machine

- VMC Table Working Area: 1000×500 mm

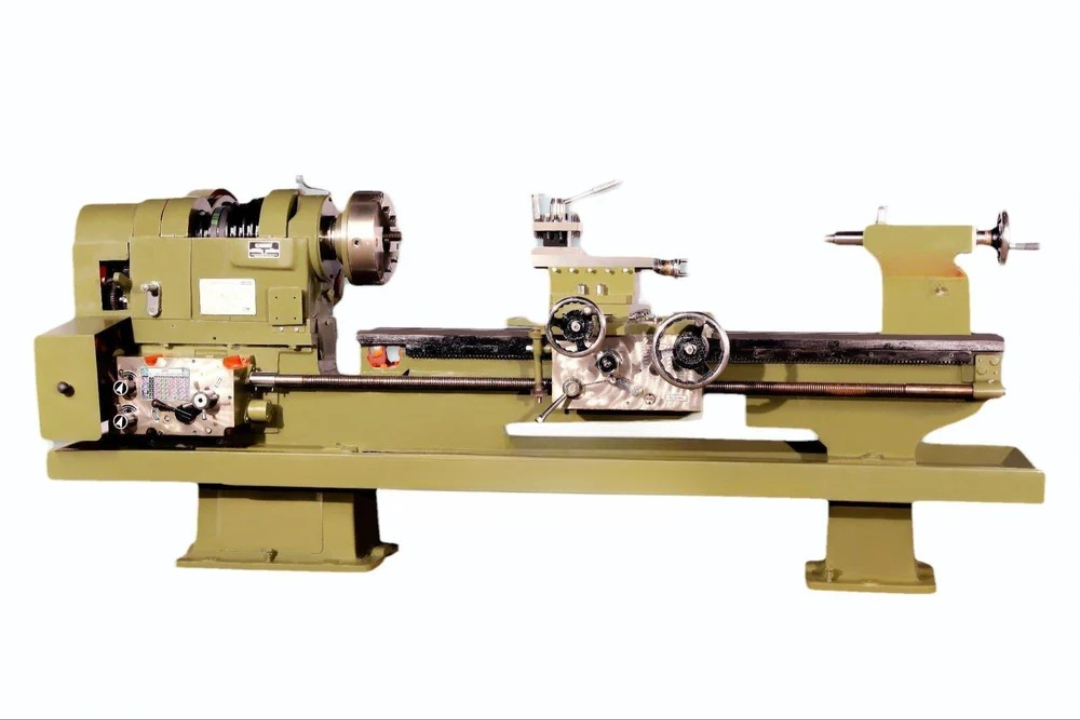

Hydraulic & Manual Lathe Machines

- Quantity: 4 Machines

- Suitable for long shaft machining and heavy-duty.

- Hydraulic Drilling: 400 mm with 50 mm dia.

Drilling, Milling & Supporting Machines

Hydraulic Drilling Machine

Quantity: 2 Machines

Standard Drilling Machines

Quantity: 2 Machines

Milling Machine

shaping

keyway cutting

Quantity: 1 Machine

MNTR Machine

Heavy-duty milling & shaping

Quantity: 1 Machine

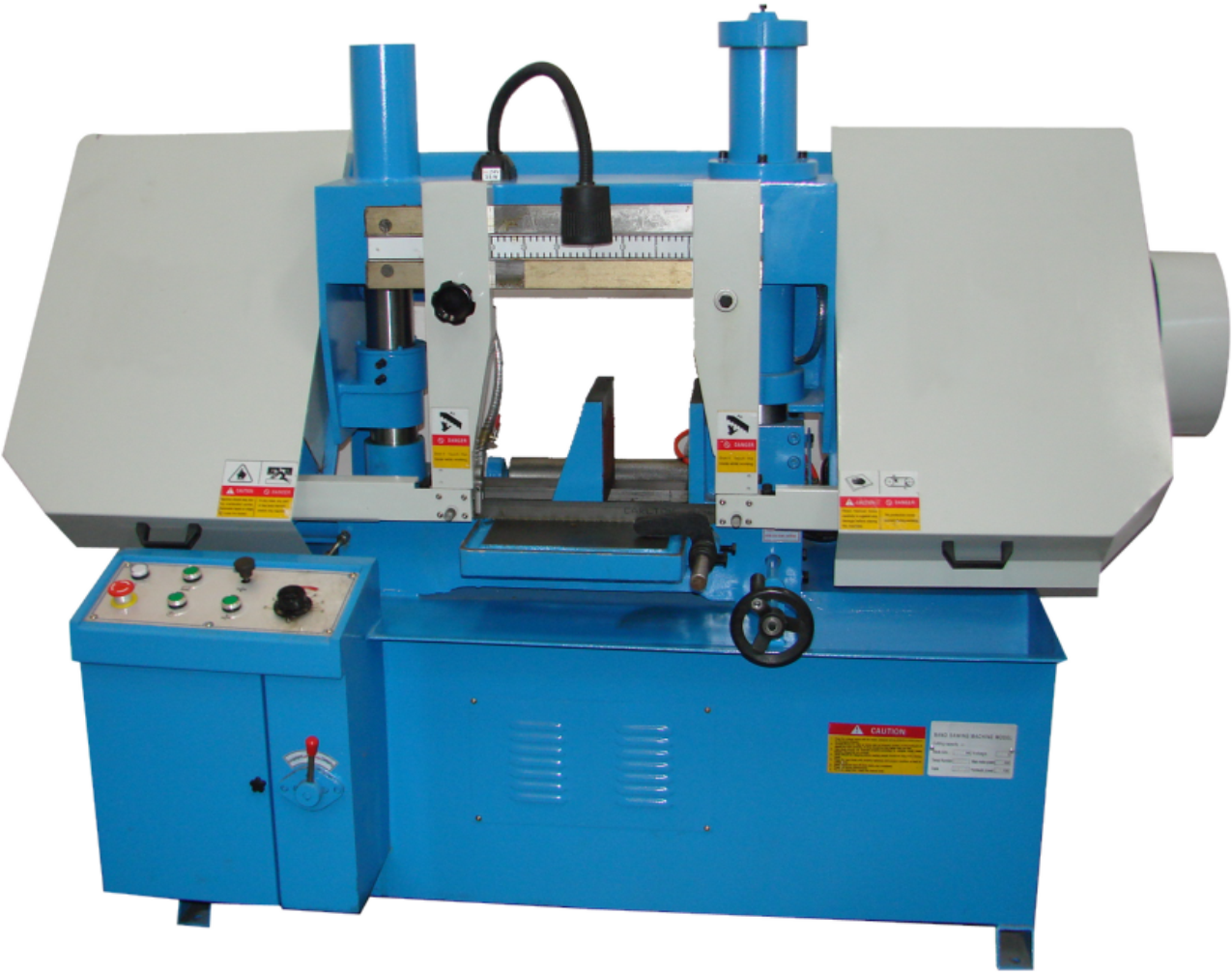

Band Saw Machine

Cutting Capacity: 250 mm

Smooth cutting for raw material preparation

Quantity: 1 Machine

Silent Generator Set

Ensures uninterrupted production

Quantity: 1

Measuring & Inspection Instruments

Our quality control department is equipped with precise measuring tools for accurate inspection.

- Vernier Calipers (4 Nos.)

- Height Gauge 300 mm (1 No.)

- Micrometers (Upto 100 mm) (4 Nos.)

- Bore Gauges (2 Nos.)

Fabrication & Custom Production Setup

- Custom metal fabrication

- Welding & assembly

- Prototype development

- Component finishing, grinding, and deburring

- Customized machining based on client drawings or samples

Manufacturing Capabilities

Our facility supports a wide range of production requirements:

- Turning Diameter: up to 350 mm

- Turning Length: up to 500 mm

- Hydraulic Drilling: 400 mm with 50 mm dia.

- Heavy Drilling: up to 50 mm dia.

- VMC Table Working Area: 1000×500 mm

- High-precision machining

Production Strengths

Capacity for Bulk & Custom Orders

We handle both low-volume specialized machining and high-volume production with equal efficiency.

Skilled Workforce

A dedicated team with years of machining and CNC VMC operation experience..

Consistent Quality Output

Regular inspection during and after production ensures defect-free results.

Efficient Workflow

Material handling, scheduling, and machining follow a structured process for fast and timely deliveries.