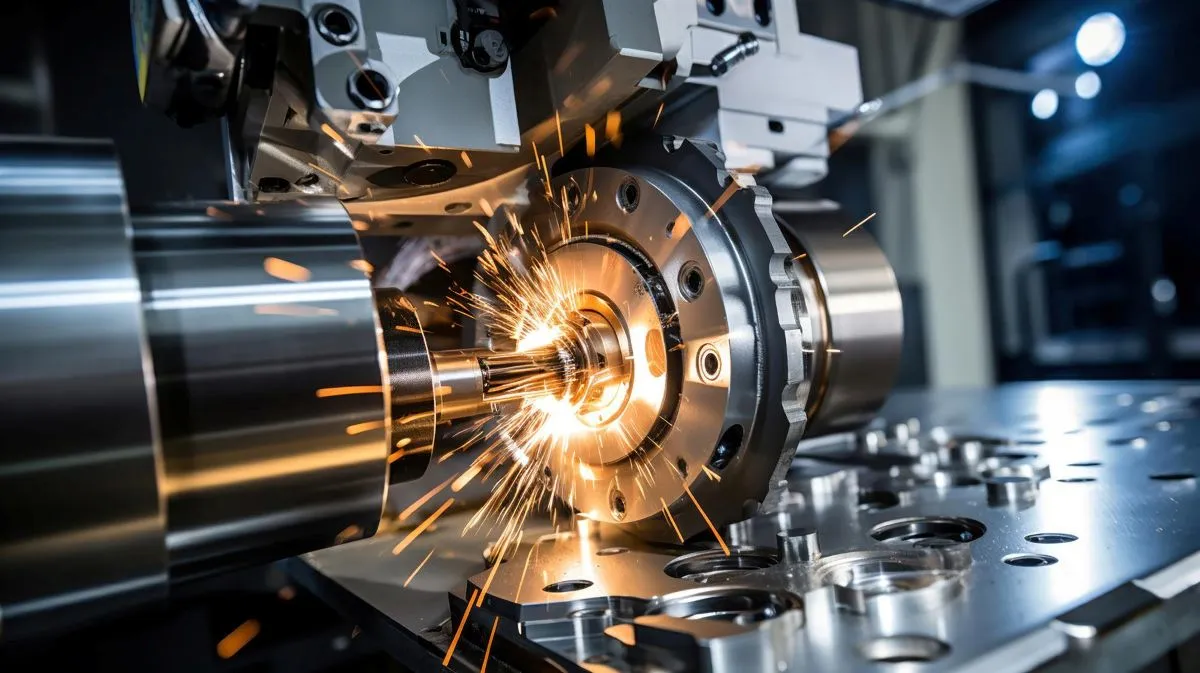

How CNC Machining Improves Product Quality & Reduces Costs

In today’s competitive market, industries want high‑quality components at optimal cost.

CNC (Computer Numerical Control) machining offers the perfect balance of quality, speed, and efficiency.

Benefits of CNC Machining

-

Reduced Human Error

CNC machines work based on digital programs, ensuring accuracy in every piece. -

Lower Production Costs

Less manual labor + faster cycle times = significant cost savings. -

Faster Turnaround Time

CNC machines operate continuously with high‑speed machining cycles. -

Better Material Utilization

Precise cutting reduces material waste during production. -

Compatibility with All Materials

CNC supports steel, aluminum, brass, copper, plastic, and more.

Why Manufacturers Prefer CNC Machining

-

High repeatability

-

Complex part creation

-

Fine finishing

-

Long-term reliability

At RJS ENGINEERING WORKS, we use advanced CNC technology to deliver cost-effective, high-precision components for all industrial needs.